In a world where Environmental, Social, and Governance (ESG) considerations are at the forefront of corporate agendas, it is critical for businesses to implement sustainability objectives into their strategies and operations.

For businesses engaged in the production or sale of goods containing or packaged in plastic, there is a significant opportunity to pivot towards more sustainable materials. This not only contributes to the wellbeing of the planet, but also aligns with wider corporate sustainable business goals. The key question is, what concrete steps should FMCG and Retailers take to make this a reality?

Unpacking the Regulatory Landscape

The EU Green Deal provides a roadmap to achieve zero greenhouse gas emissions by 2050. This includes the Plastic Strategy, a key component designed to strengthen secondary raw material markets with mandatory recycled content and specific targets to be attained by 2030 (Directive (EC) 2018/852). The targets are as follows:

- A recycling target of 50% for municipal waste by 2020, rising incrementally to 65% by 2035

- A recycling objective for all packaging material of 65% by 2025, increasing to 70% by 2030

- A plastic recycling target of 50% by 2025 and 55% by 2030

- Material-specific recycling targets for paper and cardboard (85%), ferrous metals (80%), aluminium (60%), glass (75%), plastic (55%), and wood (30%)

- A binding landfill target to reduce landfilling to a maximum of 10% of municipal waste by 2035

(Source: https://cms.law/en/int/expert-guides/plastics-and-packaging-laws/european-union)

In line with these targets, Council Decision (EU, Euratom) 2020/2053 has introduced a Plastic Tax. This tax is levied on each EU member state based on the weight of non-recycled plastic at €0.80 per kilogram. The aim is to inspire member states to reduce single-use plastic consumption, promote recycling, and stimulate the circular economy. Established in 2021, it is projected to generate approximately €6.4 billion in revenue by 2023.

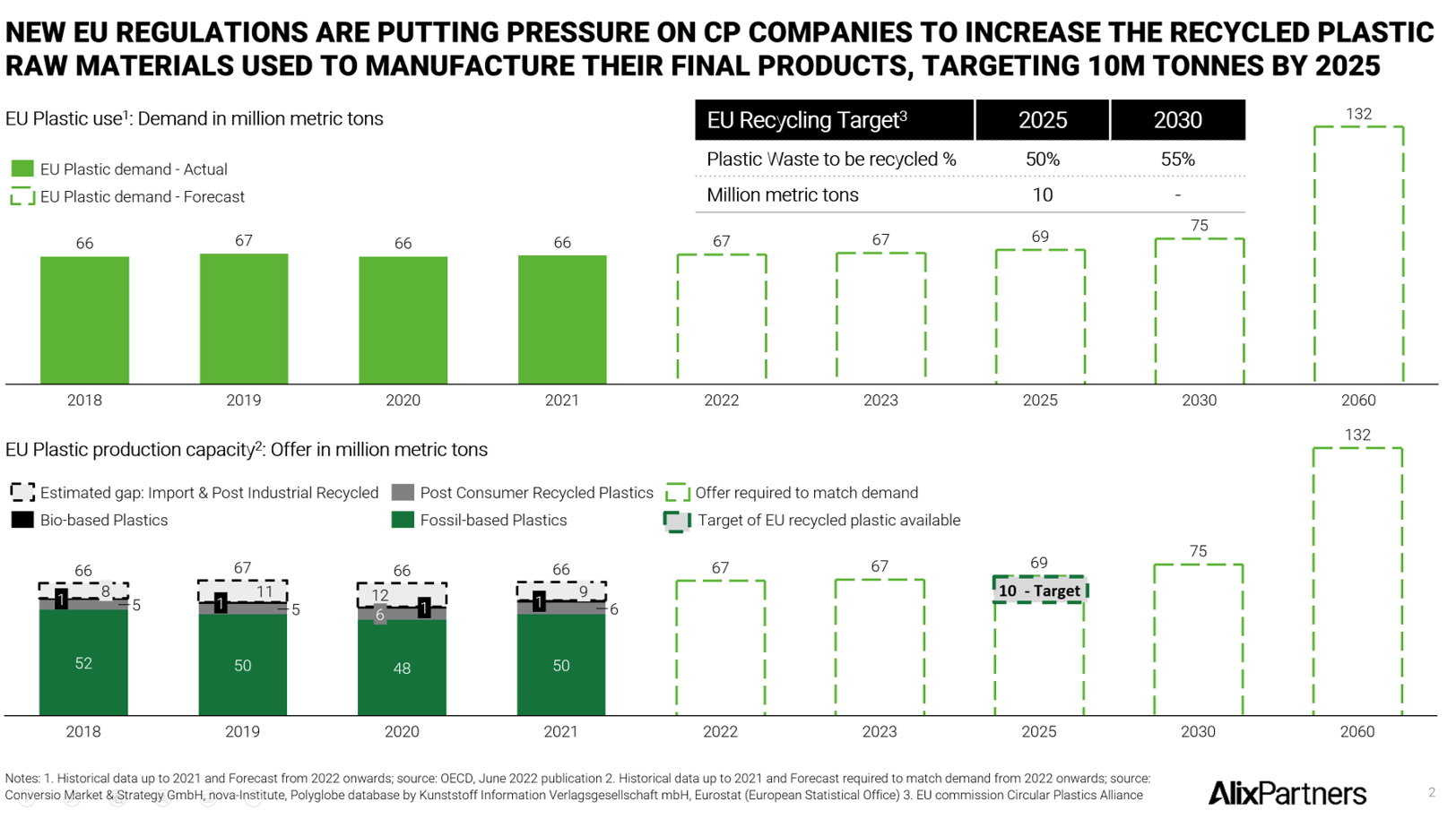

This shift towards recycled materials has significantly affected the plastic market. At times, the cost of recycled plastic has even surpassed virgin plastic raw materials. Despite the stabilisation of total EU plastic demand since 2018, growth is expected to continue, with estimates of 69 and 75 million tonnes in 2025 and 2030 respectively. New regulations are mandating an increasing proportion of this demand to be met with recycled raw materials. The initial target for 2025 is set at 10 million tonnes of recycled plastic, accounting for around 14% of the total demand.

(Sources: OECD: Economic Outlook, Volume 2022 Issue 1, June 2022 & Europa.eu: Revision of the Packaging and Packaging Waste Directive, March 2023)

Essential Steps to Establish a Recycled Materials Strategy

To keep pace with these changes, fast-moving consumer goods (FMCG) companies and retailers must develop comprehensive strategies for recycled plastic. In doing so, they will be prepared for a future where recycled plastic markets hold as much sway as virgin material markets. This proactive approach can lead to a better understanding of new legislation, ensure compliance with regulations, secure supply, and provide a competitive edge. Specifically, this involves setting recycled targets and allocating the necessary resources to achieve these objectives.

So, what is the minimum that businesses can do to establish such a strategy? We have identified 5 key pillars that businesses should focus on to form the basis of their approach:

- Identify your exposure: Understand the types and quantities of plastic used in your products

- Define your value chain: Trace the entry points of plastic raw materials or components into your value chain. This requires an understanding of the origin of raw materials, market availability, commodities indexes, import tariffs, and regulations. Also, the type of manufacturing process and technology used can affect the raw material properties needed

- Define your Key Value Proposition (KVP): This might focus on the quality, colour, tactile properties, resistance, strength, and ratio of recycled to virgin materials in your products

- Formalise raw materials requirements based on your KVP: This could involve specifying the chemical composition, type of feedstock used, colour, form of recycled raw material, key technical parameters, and usage of other agents

- Consider your place in the value chain: Make strategic decisions about outsourcing or insourcing and the type of suppliers or relationships you want to establish. Whether spot buying, multi-year contracts, or partnerships would secure your supply is also a consideration. Insourcing options like vertical integration or joint ventures could be potential alternatives

By adopting these measures, businesses not only contribute to environmental preservation, but also pave the way for a sustainable and profitable future.

At AlixPartners, we believe in both. If you would like to discuss how we are supporting businesses to improve recycled plastic production and corporate sustainable business goals, please get in touch with Andy Searle or Filippo Manca.

Looking to cut complexity and improve the transparency of your route to net zero? Learn more about Should-Carbon.